In the relentless pursuit of sustainable energy solutions, concentrated solar power (CSP) harnesses the sun’s abundant rays to generate electricity. As we strive to make renewable energy sources more efficient and reliable, the focus turns to innovations in thermal energy storage (TES). It is a critical component in optimizing the performance and scalability of concentrated solar power systems.

In recent years, the field of thermal energy storage has witnessed remarkable advancements, elevating the efficiency and viability of concentrated solar power technologies. This blog aims to delve into the forefront of these breakthroughs, exploring the cutting-edge developments that are reshaping the landscape of renewable energy storage.

Let us explore innovation, where science and engineering combine forces to shape a more sustainable and eco-friendly energy future.

Importance of Thermal Energy Storage in Concentrated Solar Power

Thermal Energy Storage (TES) plays a crucial role in Concentrated Solar Power (CSP) plants, making them more versatile and powerful tools for renewable energy generation. Here’s why it’s so important:

Overcoming Intermittency

The biggest challenge of solar power is its intermittent nature – the sun doesn’t shine 24/7. Without storage, CSP plants can only generate electricity when the sun is directly shining, limiting their usefulness. TES allows storing the collected heat during peak sun hours and using it later to generate electricity at any time, day or night. This makes CSP dispatchable, meaning it can generate power on demand, just like traditional power plants.

Grid Stability and Integration

Thermal Energy Storage (TES) is integral to Concentrated Solar Power (CSP) systems, enhancing their reliability and grid stability. Through the concentration of sunlight, CSP generates thermal energy, stored efficiently using methods like molten salt or phase-change materials. TES allows CSP plants to act as reliable backups during peak demand or outages, ensuring a stable power supply. Additionally, it facilitates seamless integration with other intermittent renewables, such as wind, addressing their intermittency issues. Overall, TES in CSP not only enables dispatchable power generation but also enhances grid reliability and supports the integration of diverse renewable sources.

Economic Benefits

By enabling dispatchable renewable energy, TES opens up new markets for CSP plants, improving their economic viability. It also allows them to participate in energy markets where they can sell stored energy at peak prices, generating additional revenue.

Renewable Energy Integration

Integrating renewables like solar and wind into the grid can be challenging due to their variable nature. TES bridges the gap by allowing excess renewable energy to be stored and used when needed, smoothing out fluctuations and enabling a more reliable and cost-effective renewable energy system.

Recent Technological Advancements

Advanced Molten Salt Technologies

The field of thermal energy storage (TES) is undergoing exciting transformations, and molten salt technology sits at the forefront of these advancements. Two key innovations are pushing the boundaries of what’s possible:

Two-tank molten salt systems

Imagine storing heat in two separate tanks, one for scorching-hot molten salt and another for its cooler counterpart. This is the essence of two-tank systems. This innovation breaks away from the traditional single-tank approach, unlocking several advantages:

Higher Operating Temperatures: These systems can reach temperatures of 700°C, indicating a 20% higher efficiency. This opens doors to integrating advanced thermodynamic cycles that can squeeze out even more energy.

Reduced Heat Loss: Separating the hot and cold tanks minimizes energy loss, ensuring your stored heat stays potent.

Greater Flexibility: This system independently controls temperatures in each tank, tailoring to storage needs.

However, like any groundbreaking idea, challenges exist. Designing these systems requires more components, raising potential costs. And finding materials that can handle both the heat and the corrosive nature of molten salt is no easy feat. Despite these hurdles, pilot projects like Crescent Dunes prove the feasibility of this approach, paving the way for future advancements.

Direct molten salt receiver concepts

These systems can attain temperatures as high as 700°C, showcasing a noteworthy 20% increase in efficiency. This accomplishment signifies enhanced performance and creates opportunities for integrating advanced thermodynamic cycles, thereby extracting additional energy.

Reduced Complexity: Fewer components translate to a simpler design, potentially lowering costs and maintenance needs.

Improved Efficiency: Eliminating the extra heat transfer step means less energy loss, boosting overall efficiency.

But simplicity comes with its own set of challenges. Finding materials that can withstand both the intense heat and direct contact with molten salt is a significant hurdle. Additionally, ensuring uniform heating and flow of molten salt within the receiver requires careful design considerations. While currently in the research phase, the potential rewards of this approach make it a technology worth watching.

Next-Generation Phase-Change Materials (PCMs) for Energy Storage

Phase-change materials (PCMs) have been gaining traction in the world of thermal energy storage due to their ability to store and release large amounts of heat at specific temperatures. However, traditional PCMs often face limitations like flammability, corrosion, and incompatibility with other materials. This is where next-generation PCMs come in, offering exciting advancements for various applications, including thermal energy storage for CSP.

Microencapsulation

Microencapsulation is a process where tiny particles of substances are coated with a protective layer, typically composed of polymers. This coating shields the encapsulated material, allowing for controlled release under specific conditions. This approach offers several advantages:

Leakage Prevention: Encapsulation prevents PCMs from leaking, addressing a major concern with their use in practical applications.

Improved Compatibility: The capsules can be designed from materials compatible with other components in a system, facilitating easier integration into existing CSP setups.

Targeted Applications: Tailoring the capsule material allows for targeting specific applications, such as integrating encapsulated PCMs directly into building materials for passive heating/cooling.

However, challenges remain, such as potential increases in cost and weight due to the added capsule material.

Composite PCMs

Composite Phase Change Materials (PCMs) are advanced materials that combine traditional phase change materials with additional substances to enhance their overall performance. These composites typically include polymers, nanoparticles, or other additives, serving to improve the thermal conductivity, stability, and reliability of the PCM. This offers benefits like:

Tailored Temperature Ranges: Combining PCMs with complementary melting points, creates a composite material that melts and releases heat within a desired temperature range, perfectly suited for a specific application.

Enhanced Performance: Combining PCMs with specific properties (e.g., high energy density, good thermal conductivity) can lead to composite materials with superior performance compared to individual PCMs.

Developing effective composite PCMs requires careful selection and characterization of individual PCMs to ensure compatibility and achieve desired properties.

Innovative Heat Transfer Fluids

Molten Metals

Molten metals stand out as innovative heat transfer fluids, particularly in applications like concentrated solar power systems. Operating at exceptionally high temperatures, such as liquid sodium or potassium, these metals exhibit superior thermal conductivity, ensuring efficient heat exchange. Benefits include:

Ultra-High Operating Temperatures: Molten metals can operate at temperatures exceeding 800°C, ideal for high-performance CSP applications and industrial processes.

Compact Storage Systems: Their high energy density allows for smaller and more compact TES systems compared to traditional fluids.

Challenges include managing their reactivity and corrosion potential, requiring specialized containment materials and system designs.

Organic Heat Transfer Fluids

Organic Heat Transfer Fluids (HTFs) are specialized liquids used in various industrial processes for efficient heat transfer. Composed of organic compounds such as synthetic hydrocarbons or silicones, these fluids excel in high-temperature applications, offering thermal stability and low volatility. Its benefits include:

Sustainability: Derived from renewable and biodegradable sources like vegetable oils, they contribute to a more sustainable energy sector and reduce reliance on fossil fuels.

Good Performance: Certain oHTFs exhibit thermal properties comparable to traditional fluids, making them viable alternatives in many applications.

Lower Flash Points: Some oHTFs offer lower flash points than synthetic fluids, potentially reducing fire risks in TES systems.

Ionic Liquids

Ionic Liquids (ILs) are unique and versatile materials known for their molten salt-like properties, composed entirely of ions. Unlike traditional salts, ILs are in a liquid state at relatively low temperatures, often below 100 degrees Celsius. Some of its advantages are:

Wide Operating Temperature Range: Some ILs can endure extreme temperatures, expanding the potential operational range of Thermal Energy Storage (TES) systems and improving overall efficiency.

Tailorable Properties: Their chemical structure allows fine-tuning properties like thermal conductivity, viscosity, and stability for specific needs.

Chemical Stability: They exhibit high chemical stability and resistance to degradation, potentially leading to longer lifespans and lower maintenance costs.

Thermal Storage with Thermochemical Processes

Stepping away from traditional sensible and latent heat storage methods, thermochemical processes offer a unique approach to storing thermal energy. Let’s explore this technology in more detail:

The Basic Idea:

Unlike using sensible heat (raising material temperature) or latent heat (changing material phase), thermochemical processes rely on reversible chemical reactions to store and release heat. Imagine absorbing heat to trigger a reaction that stores energy, and then reversing the reaction to release heat when needed. It’s like a chemical battery for heat.

Advantages of Thermochemical Storage:

Higher Energy Density: Compared to sensible and latent heat methods, thermochemical storage can store significantly more energy per unit volume, potentially leading to more compact systems.

Wide Temperature Range: Different reactions operate at different temperatures, allowing storage at specific temperature ranges suitable for various applications.

Off-Peak Charging: You can store heat during off-peak times when energy is cheaper or abundant (e.g., using solar energy during the day) and release it later when needed, creating a flexible and dispatchable energy source.

Applications of Thermochemical Storage:

Concentrated Solar Power (CSP): Storing excess solar heat and releasing it to generate electricity on demand, enhancing the dispatchability of CSP plants.

Building Heating and Cooling: Storing heat or cold during off-peak hours for efficient and sustainable building climate control.

Industrial Process Heat: Recovering and storing waste heat from industrial processes for later use, improving energy efficiency and reducing emissions.

Novel Materials and Designs

Beyond established technologies, exciting advancements are happening in novel materials and designs for thermal energy storage (TES):

High-temperature concrete:

The integration of phase-change additives, such as paraffin waxes or salt hydrates, into concrete, offers the capability to store and release heat at predefined temperatures. This innovative approach enhances the thermal performance of concrete structures, providing a versatile solution for controlled temperature management in various applications. Its advantages include:

Cost-Effectiveness: Concrete is a relatively inexpensive material, making this approach potentially cheaper than traditional TES methods.

Lower Temperature Applications: Its suitable temperature range (up to around 200°C) is ideal for smaller CSP plants or district heating/cooling systems where high temperatures aren’t required.

Scalability: The widespread availability and ease of working with concrete allow for scalable storage systems.

Nanomaterials

Envision materials characterized by extraordinary thermal properties. In the domain of Thermal Energy Storage (TES) applications, researchers are actively investigating nanomaterials, including graphene, carbon nanotubes, and metal nanoparticles. This class of materials presents a range of advantages:

High Thermal Conductivity: Nanoparticles can significantly enhance heat transfer within storage materials, leading to faster charging and discharging cycles and potentially more compact systems.

Tailored Properties: By manipulating the structure and composition of nanomaterials, their properties can be optimized for specific temperature ranges and applications.

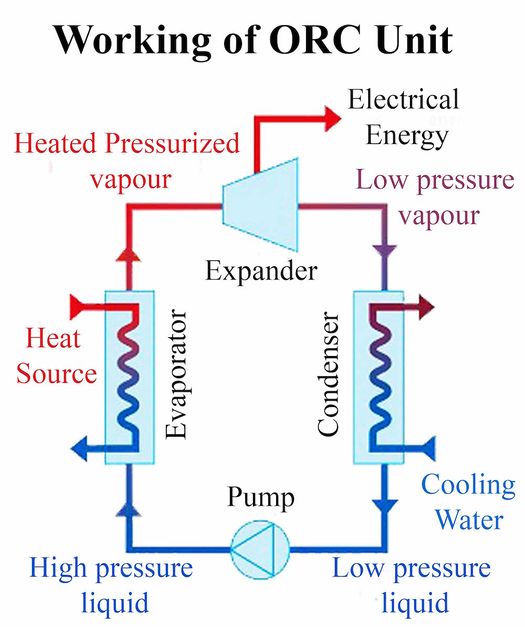

Organic Rankine Cycle (ORC) integration

Contemplate the notion of waste heat being granted a secondary purpose. In the context of Thermal Energy Storage (TES) systems, the charging or discharging processes frequently yield waste heat. The integration of an Organic Rankine Cycle (ORC) system with TES presents an innovative solution, harnessing this waste heat to generate supplementary power. This integration provides the following advantages:

Improved Efficiency: By extracting useful energy from waste heat, the overall efficiency of the TES system increases, maximizing energy utilization.

Additional Power Generation: The ORC system can generate electricity using the extracted waste heat, providing an additional source of power.

Conclusion

In the ever-evolving landscape of sustainable energy solutions, CSP stands as a beacon, utilizing the sun’s abundant rays to generate electricity. The quest for greater efficiency and reliability in renewable energy sources directs our attention to innovations in TES. A pivotal element in optimizing the performance and scalability of concentrated solar power systems, recent advancements in TES underscore its crucial role in shaping a more sustainable and eco-friendly energy future.

As we navigate the intersection of science and engineering, these breakthroughs promise to reshape the renewable energy storage landscape, offering a glimpse into a future where efficiency and environmental consciousness coexist harmoniously.

Check out our monthly newsletters, upcoming blogs, and the latest industry news to stay on top of the renewable energy game.