In the pursuit of sustainable energy solutions, scientists and engineers have continuously explored innovative methods to harness and utilize renewable resources. One such groundbreaking technology that has gained considerable attention in recent years is the Organic Rankine Cycle (ORC). As the world grapples with the challenges of climate change and seeks to reduce carbon emissions, the ORC offers a promising avenue to generate clean and efficient power.

Let us delve into the Organic Rankine Cycle and how it can boost renewable energy. We will uncover how this innovative technology has the potential to revolutionize the energy landscape, providing sustainable solutions for power generation in various industries and reducing our dependence on fossil fuels.

What is an Organic Rankine Cycle (ORC)?

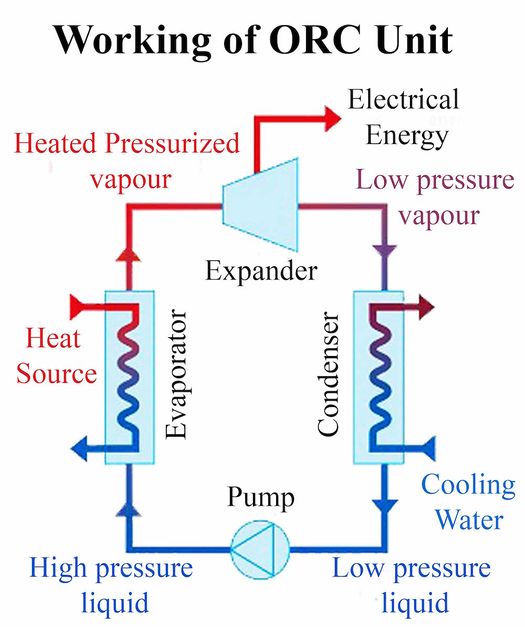

The Organic Rankine Cycle (ORC) is a thermodynamic process that effectively converts low-temperature heat sources into mechanical energy, ultimately producing electrical power within a closed system. While it shares similarities with the Rankine Steam Cycle¹, the ORC distinguishes itself by employing different fluids to facilitate energy generation.

In the Rankine Steam Cycle, thermal power is utilized to transform water into steam, which subsequently expands through a turbine, leading to the generation of electricity. However, the Organic Rankine Cycle takes a different approach. Instead of using water as the working fluid, it relies on an organic fluid characterized by a lower boiling point, considering water’s boiling point of 100℃. By employing an organic fluid with a low boiling point, the ORC is able to harness heat at lower temperatures and convert it into useful mechanical energy.

To ensure optimal performance throughout the cycle, the ideal fluid for the Organic Rankine Cycle should possess both a low boiling point and a low freezing point. This enables the fluid to vaporize at low temperatures while also avoiding solidification during the operational process.

How Does the Organic Rankine Cycle Work?

An ORC system utilizes heat energy to generate electricity, which is similar to heat pumps that use heat or thermal energy as their energy source. However, they do so in various ways.

The ORC system is designed in such a way that the thermal energy source supplies the evaporator to drive the expander or “reverse compressor,” which in turn generates electricity. On the other hand, heat pumps are devices that use electricity to transfer heat from a lower-temperature source to a higher-temperature sink. They don’t generate electricity directly from heat but rather provide heating or cooling by transferring heat from one location to another.

Different Heat Sources

The ORC uses an organic working fluid with a low boiling point, such as an organic compound or hydrocarbon, to capture and transfer heat to a turbine. Natural resources, such as geothermal energy, biomass industrial waste heat sources, or solar thermal energy, can serve as excellent heat suppliers. The heat causes the working fluid to vaporize, which expands and drives a turbine. The turbine is linked to a generator, where the mechanical energy harnessed from the expanding vapor is transformed into electrical energy. Hence, an ORC system is considered a good sustainable resource, as it used existing heat energy that would otherwise be lost in the atmosphere.

To ensure the efficient operation of an ORC system, heat exchangers play a critical role and are used in multiple stages of the cycle. They function as condensers, evaporators, regenerators, or economizers. To achieve the most reliable and sustainable electricity generation, it is crucial to employ optimal plate heat exchanger technology.

How the Organic Rankine Cycle Can Boost Renewable Energy?

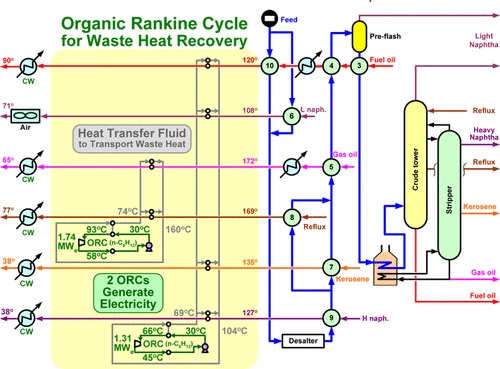

Waste Heat Recovery

Waste heat recovery has emerged as a crucial advancement in the field of Organic Rankine Cycle (ORC) systems. In this process, a low boiling point organic fluid is employed as the working medium to capture and utilize waste heat. However, certain heat sources, such as hot exhausts from furnaces, may contain sulfide compounds, both organic and inorganic in nature, which pose a risk to the integrity of the evaporator pipes. These sulfide compounds can cause damage through mechanisms such as corrosion and sulfide stress cracking.

To mitigate damage in the waste heat recovery system of an ORC, an intermediate medium like water or heat transfer oil is used. This medium acts as a buffer, minimizing direct contact between the hot exhaust gases and the evaporator pipes, reducing corrosive effects from sulfide compounds. If water is chosen, precautions are necessary to prevent freezing below 0℃, which can lead to issues like expansion and pipe damage. Solutions include adding anti-freezing agents, using heat tracing to maintain temperatures above freezing, and applying insulation to minimize heat loss.

In addition to water, various heat transfer oils are used in ORC systems. These include thermal fluids such as Dowtherm, Therminol, or Globaltherm, which have high boiling points, low freezing points, and good thermal stability. Mineral oils, such as transformer oils or industrial-grade lubricating oils, can also serve as heat transfer fluids. The specific choice of heat transfer oil depends on factors like operating temperature range, system design, safety considerations, and compatibility with other system components.

ORC systems are available in various sizes, ranging from kilowatts to megawatts, allowing for their widespread adoption in low-grade temperature applications. These systems provide significant environmental benefits by capturing waste heat from electrical and mechanical power generation processes, reducing the dependence on fossil fuels, and enhancing overall energy efficiency.

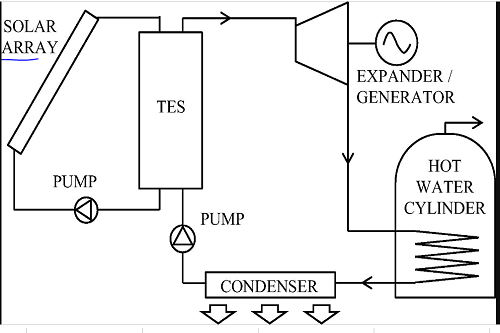

Solar-based ORC

Solar thermal collectors absorb the heat energy from solar radiation, and this heat is transferred to the organic fluid used in the Organic Rankine Cycle (ORC). The organic fluid is then stored in the Thermal Energy Storage (TES). Next, the organic fluid is pumped through the expander to produce mechanical energy at the output. This mechanical energy, thus produced, is converted to electrical power using generators.

The relatively lower temperature organic fluid from the expander is then passed through the hot water cylinder to produce hot water. Finally, the organic fluid passes through the condenser and transfers the remaining heat to increase the air temperature, which can be used for space heating applications. Therefore, one system can produce not just electricity but can also be used for space heating and hot water requirements in both domestic and commercial buildings.

Solar-based ORC poly-generation systems can provide a range of outputs, expanding beyond electricity generation alone. These systems can also deliver other valuable forms of energy, such as cooling, heating, drying, and desalination. The versatility of these systems allows for the efficient utilization of solar energy across multiple applications, maximizing the overall energy yield and providing diverse benefits.

The combination of solar-based ORC systems with poly-generation units not only enhances energy efficiency but also allows for the utilization of multiple valuable outputs, offering a holistic and sustainable energy solution. By harnessing solar energy and integrating it into a versatile and flexible system, solar-based ORC poly-generation systems contribute to a cleaner and more sustainable energy future.

Where is the Organic Rankine Cycle Used?

The ORC market has received significant attention recently due to its ability to harness renewable energy sources and waste heat. Conducting a regional analysis of the ORC market allows for insights into the specific trends, dynamics, and opportunities within different geographical areas.

Here are some examples of country-specific applications of ORC:

Italy: Italy has been a leader in the development and deployment of ORC systems, particularly in the geothermal sector. The country’s extensive geothermal resources have allowed for the establishment of geothermal power plants utilizing ORC technology for electricity generation.

Germany: Germany has implemented ORC systems in combined heat and power (CHP) applications, where waste heat from industrial processes is utilized for both electricity and heat generation. These systems contribute to energy efficiency and emission reduction goals in the country.

The United States: In the United States, ORC technology has been adopted in various sectors. It is utilized in geothermal power plants, waste heat recovery systems in industrial facilities, and biomass-to-energy applications. The U.S. Department of Energy has supported research and development efforts in ORC technology to promote its deployment across the country.

China: China has a significant focus on renewable energy and has integrated ORC technology into multiple applications. This includes geothermal power generation, waste heat recovery in industries, and biomass-to-energy projects. China’s commitment to clean energy development has driven the adoption of ORC systems.

Japan: Japan has implemented ORC systems in various sectors, including waste heat recovery from industrial processes, biomass power plants, and solar thermal power generation. The country’s interest in energy efficiency and renewable energy technologies has propelled the use of ORC in diverse applications.

Iceland: Given its abundant geothermal resources, Iceland extensively employs ORC technology in geothermal power plants for electricity generation. The country’s commitment to utilizing its geothermal potential has made it a prominent user of ORC systems.

Note: The ORC technology is not limited to these countries alone and is applied worldwide in diverse contexts based on regional energy needs, resource availability, and sustainability goals.

Conclusion

The Organic Rankine Cycle presents a promising solution for boosting renewable energy utilization. The ORC’s ability to operate with a wide range of heat sources, including solar, geothermal, biomass, and waste heat, makes it a versatile technology that can be integrated into diverse energy systems. This flexibility enables the ORC to maximize the use of available renewable resources and minimize dependence on fossil fuels.

By utilizing the ORC technology, we can tap into untapped sources of renewable energy, contributing significantly to reducing greenhouse gas emissions. As the world continues its transition towards a clean and sustainable energy future, the Organic Rankine Cycle stands as a key enabler for unlocking the potential of renewable energy sources.

Learn more about such innovative technologies and more in our blogs. Get solar industry updates through our industry news sections and don’t forget to subscribe to our monthly newsletter!

¹ Rankine Steam Cycle is a process used by power plants such as nuclear reactors or coal-fired power plants. A fuel is used to generate heat within the boiler that is used to convert water to steam and expands through a turbine producing useful work (transfer of heat energy into mechanical energy which is then used to generate electricity).