In an era driven by rising clean energy demands and the rapid growth of electric vehicles, lithium batteries have become crucial catalysts for a greener future. Yet, this heightened demand has unveiled a multitude of challenges with regard to lithium mining.

Serving as the foundation of rechargeable batteries, lithium has sparked transformative changes across industries and daily life, offering a cleaner and more efficient substitute for traditional fossil fuels.

However, the surging demand for lithium also presents a complex tapestry of environmental and ethical concerns. This article not only explores eco-friendly approaches to lithium mining but also investigates the potential of hydrogen fuel cells as a promising alternative technology.

What Does Lithium Mining Entail

Where Is It Found?

Lithium, an active alkali metal, boasts great heat and electrical conductivity. It’s also efficiently used in producing pharmaceuticals, lubricants, glass, and lithium-ion batteries for consumer electronics.

Due to its high reactivity, lithium isn’t found in its pure form in nature. Instead, it exists as part of salts or other compounds. Lithium commonly found in the market is typically in the shape of lithium carbonate, which is a more stable compound that can be subsequently transformed into different chemicals or salts.

Lithium salts can be found within subterranean reserves, such as clay, mineral ore, brine, geothermal water, and even seawater. The majority of global lithium is obtained from mining operations. Particularly high concentrations of lithium are found in briny lakes, known as salars, where levels range from 1,000 to 3,000 parts per million.

Lithium Extraction

The regions of Bolivia, Argentina, and Chile encompass areas referred to as the lithium triangle, boasting the highest concentrations of lithium. The lithium extracted from these salars primarily takes the form of lithium carbonate, serving as the primary raw material employed by companies in the production of lithium-ion batteries.

The process of brine mining in salars takes an extended period, ranging from eight months to three years. It starts with drilling a hole and pumping brine to the surface. The extracted brine is then left to evaporate naturally for several months, resulting in a mixture of manganese, borax, potassium, and salts.

Afterward, this mixture is filtered and moved to a separate pool for additional processing. The filtration process will take between 12 and 18 months to extract lithium carbonate, also known as “white gold”.

The Risks Of Lithium Mining

The filtration process proves cost-efficient and reliable but it demands a substantial amount of water, estimated at around 500,000 gallons per ton of extracted lithium.

This exerts substantial pressure on local communities, as seen in Chile’s Salar de Atacama. Mining has caused a severe 65% water reduction, impacting farmers who rely on agriculture and livestock for their livelihoods.

The absence of water in the area isn’t the only issue linked to lithium mining. There’s also the risk of hazardous substances seeping from the evaporation pools into the water supply, including hydrochloric acid used during lithium processing, along with waste byproducts that can leach out from the brine.

In the United States, Canada, and Australia, lithium is often obtained from rock using conventional techniques. However, even these methods require the application of chemicals for practical extraction. In Nevada, the research discovered adverse effects on fish situated 150 miles downstream from a lithium processing facility, illustrating the potential ecological repercussions.

A report from Friends of the Earth highlights that lithium extraction can detrimentally impact soil quality and lead to air contamination. In Argentina’s Salar del Hombre Muerto region, residents voice concerns over lithium pollution of streams that are vital for human and livestock use. Similarly, in Chile, there are clashes between mining companies and local communities.

Sustainable Lithium Mining Opportunities

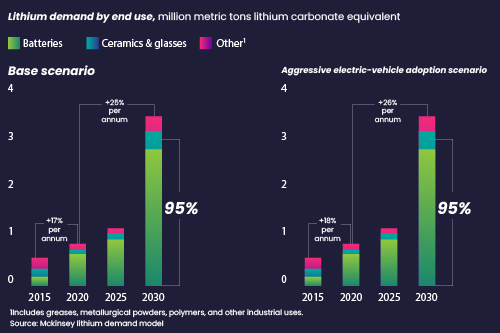

By 2030, batteries are projected to make up 95% of lithium demand. The annual growth of 25% to 26% will drive the total requirement to 3.3 million to 3.8 million metric tons of LCE (lithium carbonate equivalent), depending on the scenarios depicted in the graph.

As the demand for lithium continues to increase due to its essential role in batteries for electric vehicles (EVs) and renewable energy storage, several sustainable mining prospects are coming to the forefront. Here are a few instances:

Closed-Loop Recycling: Developing technologies to recover lithium from used batteries and other sources, promoting a circular economy and minimizing the need for new mining.

Reducing Water Usage: Utilizing water-saving technologies and techniques during lithium extraction from brine sources to mitigate the impact on local water resources.

Renewable Energy Integration: Powering mining operations with renewable energy sources, such as solar and wind, to reduce carbon emissions associated with mining activities.

Community Engagement: Involving local communities in decision-making processes and ensuring that mining operations provide socio-economic benefits and contribute to local development.

Waste Management: Developing efficient methods for managing and repurposing waste generated during lithium extraction, processing, and production.

Carbon Offsetting: Compensating for the carbon emissions associated with mining through carbon offset projects, such as reforestation and renewable energy initiatives.

Lithium Recovery from Geothermal Brines: Extracting lithium from geothermal brines during geothermal energy production can yield a sustainable source of lithium while enhancing the value proposition of geothermal energy.

Regenerative Mining Practices: Implementing regenerative approaches that prioritize ecosystem restoration and biodiversity conservation alongside mining activities.

Are Fuel Cell Electric Vehicles (FCEVs) an alternative to Lithium-Ion Batteries?

Hydrogen Fuel Cell Electric Vehicles (FCEVs) are indeed an alternative to Lithium-Ion Batteries when it comes to powering electric vehicles, and they represent two distinct approaches to electrified transportation. Here’s a comparison of the two:

| Hydrogen Fuel Cell Electric Vehicles | Lithium-Ion Batteries | |

| Energy Storage | FCEVs use hydrogen stored in high-pressure tanks as a fuel source. In a fuel cell, hydrogen combines with air’s oxygen to generate electricity, which propels the vehicle’s electric motor. | Lithium-ion batteries store a large amount of energy in a compact and lightweight form using chemical reactions. |

| Refueling/Charging | FCEVs refuel with hydrogen at dedicated hydrogen stations, much like conventional gasoline or diesel vehicles. This refueling process is typically faster than recharging batteries. | They need external power sources for charging, like electric grids, stations, or home outlets, with typically longer charging times than refueling hydrogen FCEVs. |

| Range | FCEVs typically have a longer driving range compared to many battery EVs, making them suitable for long-distance travel. | EVs equipped with lithium-ion batteries typically have a limited range per charge, which is gradually improving with advancements in battery technology. |

| Charging Infrastructure | Hydrogen refueling infrastructure is less widespread compared to electric charging stations, limiting the availability of FCEVs in some regions. | Infrastructure for charging lithium-ion battery EVs is widely available and expanding, making them more practical for everyday use. |

| Environmental Impact | Hydrogen can be produced diversely, including renewably, affecting FCEVs’ environmental impact, determined by the hydrogen source. | The production and disposal of lithium-ion batteries have environmental considerations, including resource extraction and recycling. |

Conclusion

In conclusion, as the demand for clean energy and electric vehicles continues to surge, lithium remains at the forefront of innovation. Navigating the intricate challenges posed by its extraction requires concerted efforts toward sustainable practices. By embracing greener alternatives and responsibly harnessing this valuable resource, we can pave the way for a brighter, cleaner energy future.

Additionally, the rise of FCEVs offers an alternative to conventional lithium-ion batteries, highlighting the ongoing evolution of clean energy tech. Together, these advancements hold the key to a more eco-conscious and efficient future for generations to come.

Get insightful information through our blog and newsletter. Stay updated about the renewable energy sector through our industry news.